We understand your need as a supplier with expert knowledge of your industry and your specific component requirements. Our service experts are ready to assist you in meeting your design challenges with clear communications on everything from material capabilities to project status. Our sales engineers, backed by our forging development team and superior metallurgy group, can provide you with the support you need to improve component manufacturability. We strive for product and process improvements that reduce your total supply chain cost and improve your speed to market.

We constantly monitor the progress of production orders to provide the highest level of delivery reliability and communication. From initial purchase order to part delivery, your forgings will be attended by our excellent experts who care about the progress as much as you do. In addition, our scheduling system and abundant manufacturing capacity allow for daily entry of emergency orders for immediate production in rush or breakdown situations.

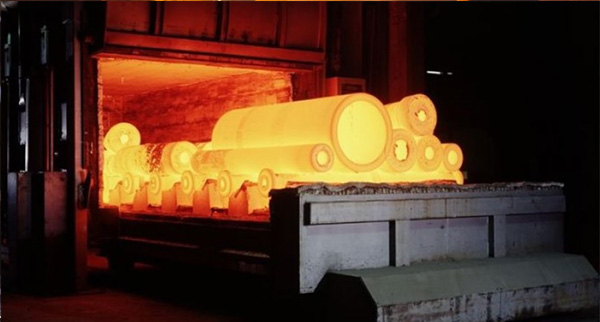

We maintain an extensive inventory of materials commonly used for your application, including 17-4PH, 2205, 316, 316L, N08825, N07718, N06625, and various modified grades tailored to meet API and customer-specific requirements. We have extensive experience working with stainless steel (austenitic, duplex, super duplex and PH grades) and nickel base alloy. This ready inventory and experience eliminate many of the delays associated with order processing.

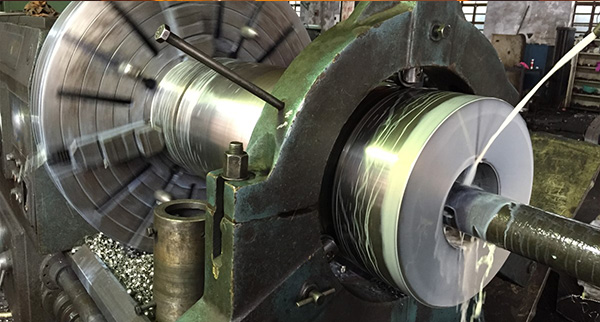

We offer all downstream value-added processes including saw cutting, heat treating, rough-peeling and machining to parts. Combined with our advanced forging technology and the inherent advantages of forging process, our capabilities provide a superior value solution.

Perfect QM system and API 6A for NDT and heat treatment, we can provide virtually any forging with good quality. Our services team is well-versed in all the process requirements from the preparation of raw materials to the inspection before delivery. Our experience working with third-party agencies and quality auditors ensures the mill certificate is accurate, complete and on time.