HUISHIH has been forging special metals to meet the increasing demands of technical and industrial markets for more than 20 years. We offer a dramatic range of products designed to meet our clients' highest expectations for quality and performance, from bars, blocks, discs, flanges, spheres and sleeves to large valve components and seamless rolled rings in a variety of materials.

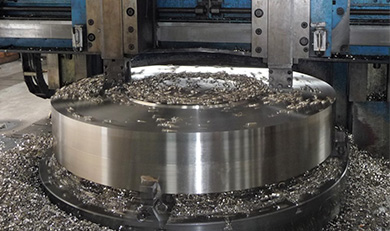

We are capable of supplying forged products fully heat treated, rough turned, finish machined and non-destructively tested according to customer requirements. When part geometry and quantities permit, semi-closed die forgings for near-net-shape parts can be manufactured.

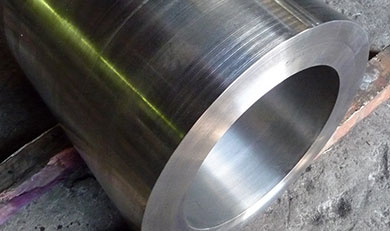

The polished or rough-peeled surface is preferable and favorable for nondestructive inspection, as we always advise. Because the micro defects are difficult to be detected via ultrasonic test (i.e. UT), due to the black, rough and uneven surface after being hot-forged. Likewise, the bright surface is also necessary for liquid penetrant test (i.e. PT).

The product ID, incl. material grade, heat number, dimension, client’s material code, will be labelled by pneumatic punch marker normally. The Package, incl. fumigated wooden case or pallet, is not only seaworthy but also strong enough to protect the products from any damage.