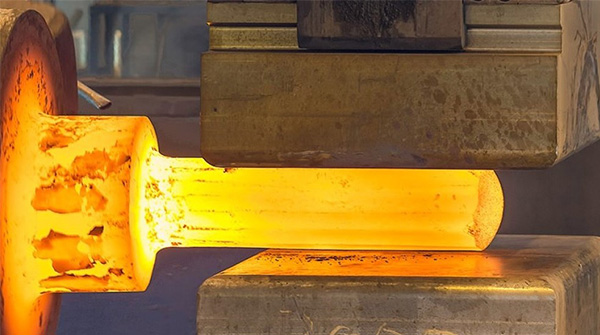

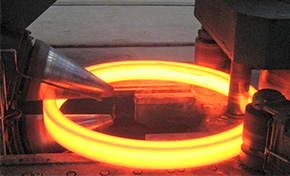

In the field of hot working of special alloy, we are dedicated to the production of various types of forgings, such as shafts, discs, rings, flanges, and the forgings with special shape.

High quality is derived from the strict control of the manufacturing process. Therefore, we conduct the strict monitoring and recording on each step in forging process, from the preparation of working instruction to the heating of steel ingots or billets, and the cooling after forging as well.

The low-sulfur fuel oil is used widely for heating by HUISHIH Alloy, in order to avoid the contamination by sulfur as a constituent deleterious to the quality of forgings. The furnace temperature is controlled and recorded automatically for the traceability of heating process.

Ultrasonic inspection is absolutely enforced for every batch of products in HUISHIH, for the avoidance of quality loss caused by the unqualified products containing dot or line defects.

The downstream processing, incl. heat treatment, rough-peeling or machining to parts, is an option as per your purchase specification.